Accelerating Steel's Environmental Leadership: A Collaborative Path to Verified EPDs

How Advanced Parameterization Technology Enables Industry-Wide EPD Infrastructure

The North American steel industry stands at a critical competitive moment. While North American steel offers superior environmental performance—including infinite recyclability and the lowest carbon intensity among major steel-producing regions globally—proving this advantage to architects, engineers, and contractors requires more than industry knowledge. It needs verified, comparable Environmental Product Declarations (EPDs) that can compete with concrete, aluminum, and engineered wood alternatives.

The Challenge: Proving What We Know to Be True

Recent market data reveals a concerning trend. Despite steel's inherent sustainability advantages, competing material industries are outpacing steel in transparent environmental reporting. The concrete and aluminum industries have invested heavily in streamlined EPD processes, making it easier for design professionals to specify their materials with confidence.

Meanwhile, many steel producers face significant barriers to EPD participation:

- High Costs: LCA modeling can cost $50,000-$150,000 per facility for comprehensive EPDs

- Time Requirements: Traditional EPD development takes 6-12 months from start to verification

- Expertise Gaps: Most facilities lack in-house LCA expertise, requiring expensive consulting arrangements

- Inconsistent Methodologies: Different consultants using varying approaches makes steel EPDs difficult to compare

- Static Reports: Facility and average product impact reports dominate the steel space, even as concrete and other industries shift to project-specific documentation

Market Urgency: The Perfect Storm

Three converging forces create unprecedented urgency for steel industry EPD collaboration:

1. Regulatory Cascade (2025-2026)

The convergence of EU CBAM requirements already in effect, SEC climate disclosure rules beginning fiscal year 2025 for large accelerated filers, GSA Buy Clean mandates for federal construction projects, and state-level chain of custody rules creates a regulatory avalanche. Steel producers need verified EPDs not just for direct compliance, but because their customers face supply chain disclosure obligations under these same frameworks.

2. Major Customer Mandates

Hyperscalers Amazon (AWS), Microsoft (Azure), and Google (Cloud)—spending $120+ billion annually on datacenter construction—now require suppliers to provide emissions baselines and reduction roadmaps. Microsoft mandates 100% carbon-free electricity by 2030 for key suppliers, while Google requires decarbonization roadmaps from major hardware providers. With datacenter construction driving 30%+ increases in their Scope 3 emissions, these aren't requests—they're procurement requirements backed by massive purchasing power.

3. LEED v5 Market Transformation

The upcoming LEED v5 rating system makes EPDs mandatory rather than optional for material credits, affecting over 2.2 million square feet of certified projects monthly in North America. Performance-based thresholds will reward steel's superior carbon intensity—North American steel averages 40% lower emissions than global competitors—but only with verified EPDs to prove it.

Learning From Industry Pioneers

The solution path is already emerging across industries. At the upcoming ACLCA conference, multiple sessions demonstrate how associations are successfully implementing collaborative EPD strategies:

- American Composites Manufacturers Association (ACMA): Trinity Consultants developed a comprehensive parameterized LCA model integrated with SmartEPD, enabling member companies to generate facility-specific EPDs cost-effectively

- Aluminum Extrusion Council (AEC): Created dynamic, on-demand EPD generation tools with scenario analysis capabilities for their member companies

- Shaw Industries: Implemented a verified EPD generator tool covering their global carpet portfolio across multiple regions and program operators

These pioneering efforts share common elements: parameterized LCA models, industry-wide collaboration, and modern platform integration.

A Collaborative Solution: Industry-Wide EPD Infrastructure Enabled by Advanced Technology

What if we approached EPD development the way the steel industry approaches everything else—through collaboration, standardization, and shared infrastructure?

Modern LCA platforms now support sophisticated parameterization capabilities that make industry-wide collaboration technically feasible. Consider this framework: modular, harmonized, member-ready LCA model templates that are 80% complete and ready for steel producer customization.

The Technology Foundation

Advanced parameterization transforms how LCA models work. Instead of building models from scratch, steel producers can customize proven templates through guided parameter inputs. This approach leverages:

Scenario Analysis: Easily evaluate different production configurations, energy sources, or raw material mixes through parameter switches—exactly what our upcoming ACLCA session will demonstrate with real steel manufacturer data.

Configuration Management: Single model templates that can represent multiple facility types or product variations through linked parameters. A single EAF template could serve mini-mills across North America by adjusting parameters for local electricity grids, scrap compositions, and throughput rates.

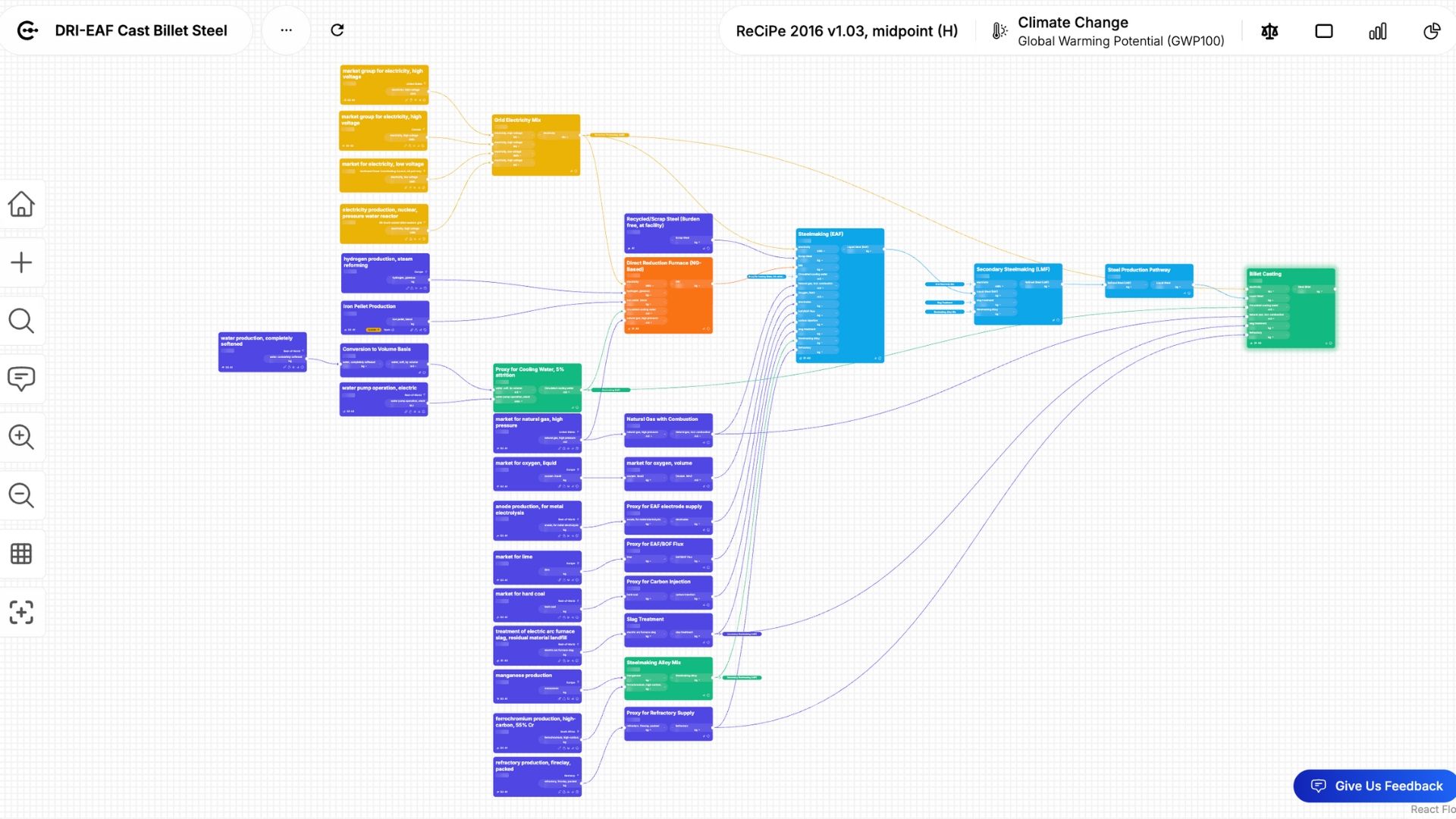

Modular Design: Complex steel production processes broken into manageable linked sub-models (raw materials, steelmaking, finishing) that can be independently validated and updated.

AI-Augmented Workflows: Modern platforms integrate AI agents to support sustainability teams throughout the workflow—helping define goals, build and refine models, and assess business impacts, as we'll demonstrate in our steel manufacturer use case.

Enable Rapid Customization

Steel producers could securely plug in facility-specific data—energy mix, alloy composition, throughput, scrap ratios—through guided interfaces. Rather than building LCA models from scratch, producers would customize proven templates using parameterized modeling that maintains methodological consistency for fair comparisons.

Ensure Methodology Consistency

All models starting from the same basic structure and Product Category Rules (PCRs) would be "pre-harmonized," enabling accurate side-by-side comparisons. This addresses the current challenge where steel EPDs developed by different consultants at different times often aren't directly comparable due to varying methodologies, software packages, and background datasets.

These templates would already incorporate:

- Appropriate Product Category Rules (PCRs)

- ISO 14044 and EN 15804 methodology compliance

- Steel-specific system boundaries and impact categories

- Integration with verified background databases

Support the Full Value Chain

These shareable models could serve as the foundation for fabricated materials, reducing time and cost barriers throughout the steel supply chain. AISC-certified fabricators could build upon verified mill-level EPDs to create project-specific environmental declarations.

The Implementation Path

A successful industry-wide initiative would require coordinated effort across multiple stakeholders:

1. Model Development

Working with established LCA consultants, the industry could develop fully customizable models for common steel processes (EAF, BOF) and product categories (plate, coil, rebar, structural sections). These templates would incorporate decades of steel industry LCA expertise into reusable frameworks.

2. Expert Review and Validation

Independent technical review would ensure models meet all relevant standards: ISO 14044, EN 15804, Buy Clean requirements, and specific EPD program operator standards. This upfront investment in methodology validation would eliminate repeated review costs for individual producers.

3. Platform-Enabled Facility Implementation

Individual producers select appropriate models and add facility data through simplified workflows enabled by modern parameterization technology. This requires only the production expertise already available in-house, without the need for deep LCA methodology knowledge, dramatically reducing EPD cost.

4. Efficient Verification

Standardized model templates would enable more efficient third-party verification processes. EPD program operators develop specialized expertise in steel industry models, reducing verification time and costs.

The Business Case for Technology-Enabled Collaboration

This approach aligns multiple industry interests while leveraging cutting-edge LCA technology:

Steel Producers gain a cost-effective path to verified EPDs, showcasing superior sustainability performance and meeting customer demands without major resource investments.

Industry Associations advance sector-wide credibility and competitiveness through scalable member solutions rather than fragmented individual efforts.

LCA Consultants expand their reach across the industry with proven, reusable models while focusing expertise on high-value customization and verification activities.

EPD Program Operators provide efficient, standards-aligned verification with industry-specific expertise at scale.

Design Professionals access consistent, comparable steel EPDs that enable confident material selection based on actual environmental performance.

Technology Providers like CarbonGraph enable the technical infrastructure that makes industry collaboration feasible through advanced parameterization, AI integration, and cloud-based collaboration.

Real-World Implementation: A Steel Manufacturer Case Study

Our upcoming ACLCA session will demonstrate these principles in action through a detailed steel manufacturer use case. We'll show how parameterized models help define reduction roadmaps, track progress, and deliver product-level insights while supporting scenario analyses and sanity checks essential for generating high-quality outputs needed for Environmental Product Declarations (EPDs) and reduction roadmaps.

The session will highlight how AI agents support sustainability teams throughout the workflow—helping define goals, build and refine models, and assess business impacts. Together, parameterization and AI reduce modeling effort, enhance consistency, and accelerate decision-making across complex value chains.

Bridging Individual and Collective Value

This approach creates a powerful dynamic: steel producers benefit individually through reduced EPD costs and faster implementation, while contributing to industry-wide transparency that enhances steel's competitive position against alternative materials.

The parameterized modeling approach means companies maintain control over their proprietary data while participating in collaborative methodological frameworks. Facility-specific parameters remain confidential while benefiting from shared modeling infrastructure.

A Call for Industry Leadership

The steel industry has always solved complex challenges through collaboration—from developing safety standards to advancing recycling technologies. EPD infrastructure deserves the same coordinated approach, enabled by modern technology platforms that make collaboration both technically feasible and economically attractive.

This perfect storm means EPDs transition from "nice to have" to "business critical" for steel producers serving infrastructure, datacenter, and commercial construction markets. The question isn't whether comprehensive EPD coverage will be required—regulatory and market forces have already answered that. The question is whether we'll build that capability efficiently through technology-enabled collaboration, or inefficiently through hundreds of individual efforts.

North American steel producers have already achieved remarkable environmental performance improvements. The challenge now is proving that performance through credible, verified documentation that design professionals can use with confidence.

Steel's environmental leadership is real. Now let's prove it—together.

Learn more about parameterized LCA modeling and AI-augmented workflows at our ACLCA session: "Powering Net Zero: Parameterized LCA Models and AI Augmented Workflows for Enterprise Scale Sustainability" - Thursday, September 18, 3:30-5:00pm, Grand Ballroom D.

What are your thoughts on technology-enabled industry collaboration for EPDs? Steel producers, consultants, and industry professionals are invited to share perspectives on this approach. Contact steel@carbongraph.io to discuss how your organization might participate in advancing steel's environmental transparency.

About CarbonGraph: CarbonGraph provides product-level life cycle assessment and carbon footprinting to help manufacturers, consultants, and educators generate fast, auditable, and reusable LCA models. Our platform supports parameterized modeling, database interoperability, and cloud-based collaboration for efficient EPD development across industries including steel, consumer goods, and building materials.

Share

Got a Product in Mind? Let's Model It Together.

Tell us what you're working on, and we'll show you how CarbonGraph can bring it to life with environmental insights.